ME360

Product Design

The following work was done mostly in class and was to be submitted as in-class assignments for participation purposes.

Martin Michael Dimo

Skateboard FEA-optimized Design

Motivation: Apply concepts of FEA analysis and optimization learned in class to design a skateboard deck.

Objectives: The main steps are as follows:

-

Preliminary design decisions

-

Choose the type of skateboard, dimensions, deck shape, and dimensions

-

Materials selection

-

Stress, strain, and deformation analysis using FEA

-

Analysis of results and design optimization for the lowest weight

Context: Skateboarding became popularized in California in the 1950s and has swept the world as a staple of youth, activity, and extreme sports. Since its inception, skateboarding has broadened into many subcategories. The most famous and longest-existing variation is the trick skateboard, which is also referred to as the popsicle deck. Other shapes can be seen in the figure below.

Popsicle (left), followed by Riptide, Point Break, and Drop-through Longboard (right)

Given Task: Design a skateboard deck that can withstand a weight of 180 pounds with a maximum deformation of 0.375 inches. The deck should be designed with a safety factor of 3, and the deck should be optimized using FEA analysis.

Considerations: Given the information on skateboards over history, they don’t tend to vary too much in size. Given the fact that the load is going to be applied over the surface area of two feet of the US size 12, the board needs to be big enough to comfortably fit that surface area. With a load of 180 pounds, the board is going to need to be strong enough to have a maximum displacement of 0.375 inches. This means that a material will need to be selected that satisfies that constraint, as well as perform within a safety factor of 3. The deck will still need to be a reasonable thickness and overall shape to classify as a skateboard and be recognizable enough to be an achievable design.

Design Process: Three materials were chosen to be analyzed to achieve the desired, lightest skateboard deck within the constraints. Each was fitted to a Solidworks part created with all considerations in mind. The materials are the following:

-

American Red Maple Wood

-

6061 Aluminum

-

High-Density Polyethylene

Skateboard deck dimensioned sketch

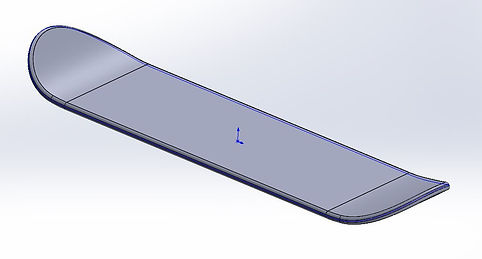

Completed skateboard deck part

Accurate projected shoe surface area for load analysis

Final engineering drawing of the skateboard deck

Results: Upon applying a static load study for each material mentioned above, plots for maximum von misses stress and displacement are calculated. These plots visually explain the effect of the applied load on the structure of the deck.

Static study model mesh with two fixtures (orange and green) and two applied loads (purple)

FEA Analysis of the skateboard deck made of American Red Maple Wood (displacement heat map)

FEA Analysis of the skateboard deck made of American Red Maple Wood (maximum stress heat map)

Evaluation: Results of running analyzes on all three materials show that American Red Maple Wood has the best optimization capabilities, allowing for a design that is only 10 mm thick with a maximum displacement of 0.1638 mm (6.45*10^-3 inches) and a safety factor of 6.5. The weight of this deck was calculated to be 726.81 grams.

Final Solidworks mass property calculation

Technical Report:

For a more detailed report, view the technical report for this assignment.